from USA vol. 68 2014.08.25 Creating cars with the help of users across the globe - Local Motors

![]()

- Arizona, here we come! En route to the microfactory

- 4 steps to co-creation

- Individual contribution and teamwork

- Designing the chassis – Make way for the expert

- Quest for safety – Testing performance with extreme driving!

- Assembly at the microfactory – Build Floor

- Working together with users – Made by you in America

- Platform for innovation – LM Labs

- Creating a community – Tapping into “Cognitive Surplus”

- Conclusion – discover the joy, enlightenment, and playful spirit

Local Motors is a relatively new company founded in the U.S. in 2007. Its innovative approach to co-create vehicles with users across the globe has attracted increasing attention. Taking advantage of the Internet, Local Motors brings consumers, designers, and engineers together enabling them to co-develop vehicles, and people who wish to purchase these vehicles help assemble them in the microfactory. It encourages co-creation every step of the way and has brought to life a brand new product development process. By transcending conventional, common practices, the company also creates new values that reflect the needs of the times. I visited the headquarters to find out more about the company and its innovative approach. (Text by Hidetoshi Fuchigami)

目次へ移動 Arizona, here we come! En route to the microfactory

I was really surprised when I learned that there was a company out there that is "working with car enthusiasts from around the world to develop cars." I didn't think something like that would be possible. It's not that easy to make cars; It's difficult enough assembling furniture at home, let alone a car. I was skeptical at first, so I just had to check it out for myself, and what do you know, it was really true.

Because a picture is worth a thousand words I wanted to go to Arizona where Local Motors and its microfactory are located and see for myself. Although I didn't think it would be possible, I went to their website, looked up the company's contact information, and reached out to them. Without delay they replied, "No problem. Just let us know when you would like to come." So I quickly made plans to visit Arizona to see if they really made cars using the Internet. When I boarded the plane for the U.S. I wasn't thoroughly convinced that something like that could be true.

I arrived at the Phoenix Sky Harbor International Airport in Arizona, rented a car, and headed 15 miles (25km) south towards the Local Motors' microfactory.

Arizona is a popular spring training destination for MLB teams. Japanese professional baseball teams have also sought refuge from the cold there. It was just as I had imagined it: nice warm weather and vast stretches of land. I enjoyed the drive south and the American scenery with humongous trailer trucks and wide, straight roads cutting across open, breathtaking terrain. 20km in, I exited the freeway and saw the sign for Local Motors. My heart began to race.

This sign lets drivers know that the Local Motors' microfactory is close by.

This sign lets drivers know that the Local Motors' microfactory is close by.

A few minutes after I saw the sign, I found the Local Motors microfactory. Under clear blue skies there it was, a warehouse like building in the middle of a huge stretch of untouched land. It looked like a spaceship that had landed to refuel. The building looked majestic, relaxed, and somehow idyllic. Excitement mounted with every minute.

Local Motors' microfactory. It serves as a manufacturing base as well as headquarters and sales office.

Local Motors' microfactory. It serves as a manufacturing base as well as headquarters and sales office.

The front entrance of the microfactory. The phrase, "A WORLD OF VEHICLE INNOVATIONS" embodies Local Motors' high aspirations.

The front entrance of the microfactory. The phrase, "A WORLD OF VEHICLE INNOVATIONS" embodies Local Motors' high aspirations.

目次へ移動 4 steps to co-creation

When I stepped across the threshold of the microfactory, I was greeted by Damien Deciercq, whom I had contacted via email. He is in charge of new businesses and co-creation with users. He welcomed me with a very warm smile and began immediately explaining what Local Motors was about, and how it develops cars with users worldwide.

The entrance of the microfactory. In the back there is a corner where people can buy various goods and car accessories. This compact space serves as both a factory and shop.

The entrance of the microfactory. In the back there is a corner where people can buy various goods and car accessories. This compact space serves as both a factory and shop.

The process by which Local Motors creates vehicles with users, in other words, the process of co-creation has 4 key steps.

1) CREATE

2) DEVELOP

3) BUILD

4) MOD

First comes the CREATE IT phase, where the basic framework and ideas are forged. Initially, when deciding what kind of car to make, the Internet community of car enthusiasts, engineers, and designers work together to select the desired specifications. Users, who have registered with the Local Motors community, can post their ideas, designs, and sketches for cars and offer constructive criticism or ideas for improvements.

Local Motors started out as a website where professionals, amateurs, enthusiasts, and wanna-be car designers could post their own designs, ideas, and rough sketches. One of the things that gave the founder of Local Motors, John B. Rogers, Jr. the idea for this website was a conversation he had with a professor at a design institute. The professor had told him, "There are many students out there who have had an excellent education, but have not been able to land jobs that allows them to put their professional training to good use."

Currently, the Local Motors' community includes over 5,000 amateur designers, engineers, and enthusiasts from 120 countries across the world. Local Motors makes an effort to ensure that they take a look at each and every submitted design and sketch and to pick up the best ideas from the collective intelligence by posting basic concepts and themes that offer design clues, and by organizing design competitions nearly once a month.

The off-road vehicle, the "Rally Fighter," released in November 2010 as Local Motors' first commercial vehicle was based on a design created by Sangho Kim, who was just a student back then. It was chosen from among 35,000 designs and sketches provided by 2,900 community members in over 100 countries.

Users' feedback posted on social media during the CREATE IT phase serves as important decision-making criteria for the DEVELOP IT phase. It also offers a quantitative perspective on potential demand for products being developed.

Users' feedback posted on social media during the CREATE IT phase serves as important decision-making criteria for the DEVELOP IT phase. It also offers a quantitative perspective on potential demand for products being developed.

The best designs chosen during the CREATE IT phase move forward to the DEVELOP IT phase. This phase involves creation of concepts that help make it possible to manufacture and sell these products, feasibility tests, and technological considerations. Here too, community members can offer feedback on vehicle specifications and design.

During the BUILD IT phase, the community can post their views on the exterior designs of the vehicles and desired options.

And during the last phase, the MOD IT phase, the community can comment on car accessories and other minor modifications.

Members of the community can stay involved even during the BUILD IT and MOD IT phases.

Members of the community can stay involved even during the BUILD IT and MOD IT phases.

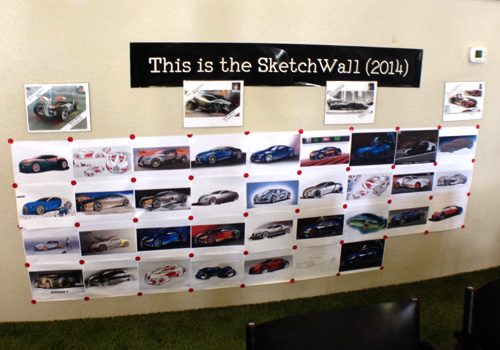

Rough sketches submitted by the community. Although members are spread across the globe, they seem to act as one, brainstorming team, with a shared focus, connected by a tight yet flexible bond.

Rough sketches submitted by the community. Although members are spread across the globe, they seem to act as one, brainstorming team, with a shared focus, connected by a tight yet flexible bond.

目次へ移動

Individual contribution and teamwork

To my question, "With so many people helping out, how do you share profits and measure contribution?" Damien replied with a wide smile, "We get asked that question all the time!"

"We're often asked how we handle intellectual property and measure contribution when developing vehicles through 'co-creation.' With the 'Rally Fighter,' Sangho Kim, who submitted the original design, received prize money when he won the design contest. And he received additional compensation once the Rally Fighter was successfully commercialized. But he wasn't the only one who contributed to the basic concept and look and feel of the car. Some people provided expertise and technical feedback, pointed out crucial issues, motivated the community with their sense of humor, helped pass out coffee and refreshments at the microfactory, and some others helped bring the team closer together. In one way or another, everyone involved contributed to the project."

The office from which Local Motors' Internet community is run. A small team of elite players helps keep operations streamlined.

The office from which Local Motors' Internet community is run. A small team of elite players helps keep operations streamlined.

A rough sketch of the "Rally Fighter." It all starts from a user's interpretation of the world and basic concept.

A rough sketch of the "Rally Fighter." It all starts from a user's interpretation of the world and basic concept.

目次へ移動 Designing the chassis - Make way for the expert

The shape and styling of the vehicles are based mainly on users' ideas. Local Motors' employees help out behind the scenes by cutting through the clutter and organizing the new values that are born from the collaboration, helping educate clients, etc. In addition, they help verify performance, safety, manufacturing feasibility, and draft policies that help bring these products to life. They manage the technical aspects of the project such as feasibility and safety that require a high level of professional expertise.

Local Motors' employees develop a light and safe chassis, which provides the foundation upon which the community designs vehicles. Only the chassis is manufactured in-house; nearly all of the other parts are out-sourced. For example, the Rally Fighter uses the same driving system as BMW, the same above-tire impact-absorption parts as Ford's dirt-race vehicles, and the same energy-absorption body shell as Mercedes-Benz.

Drawing on their technical expertise and know-how, Local Motors' employees design and develop the chassis.

Drawing on their technical expertise and know-how, Local Motors' employees design and develop the chassis.

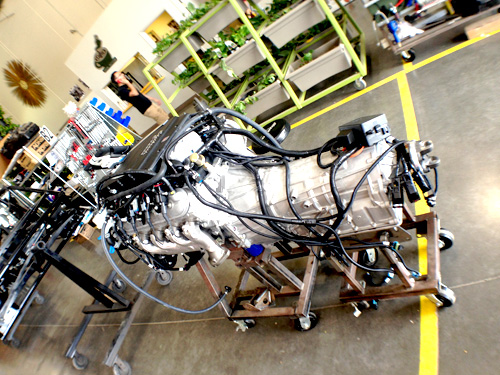

The heart of the car (the engine and power train).

The heart of the car (the engine and power train).

目次へ移動 Quest for safety - Testing performance with extreme driving!

Damien turned to me and said, "When you're ready, follow me outside." So I stepped outside just in time to see the Rally Fighter drive up.

"Ready? Let's go!"

"What?"

"We're very serious when it comes to the safety of our cars. We like to make sure that it can handle all sorts of driving. Come on! Get in!"

The Rally Fighter makes a bold, dramatic entrance.

The Rally Fighter makes a bold, dramatic entrance.

I got to test drive the Rally Fighter!

Local Motors tests the durability and safety of its vehicles in-house. Employees, who are engineers/very skilled race drivers, take the cars off-road, testing it under extreme driving and drifting.

目次へ移動 Assembly at the Microfactory - Build Floor

Local Motors continues to work together with users even after the DEVELOP IT phase. Once someone buys the car, he/she will come to the microfactory to help build it. Even if people have never built cars before (of course most people haven't!), trained professionals at Local Motors will be there to offer technical guidance and know-how.

For example, with the "Rally Fighter," Local Motors provided pick-up at the airport as well as food and accommodations. And the buyer spent 6-days in the microfactory, and then drove the finished car home.

Microfactory's "Build Floor." It's open from 8:00am to 5:30pm on weekdays. You'll find car parts, film for car wrapping, carbon fiber materials, etc. In this colorful, crowded area, you will also find space where users and Local Motors' employees can take coffee breaks, exchange ideas, etc.

Microfactory's "Build Floor." It's open from 8:00am to 5:30pm on weekdays. You'll find car parts, film for car wrapping, carbon fiber materials, etc. In this colorful, crowded area, you will also find space where users and Local Motors' employees can take coffee breaks, exchange ideas, etc.

Here you'll find all the tools you will need.

Here you'll find all the tools you will need.

All the necessary nuts, bolts, and wiring are here, too.

All the necessary nuts, bolts, and wiring are here, too.

There are no production lines. Each vehicle is built by hand. On the ceiling there are flags from around the world that remind you that the Local Motors' community is truly global with members from over 120 countries.

There are no production lines. Each vehicle is built by hand. On the ceiling there are flags from around the world that remind you that the Local Motors' community is truly global with members from over 120 countries.

目次へ移動

Working together with users - Made by you in America

I was simply curious at first, but during my visit I was truly blown away, thoroughly convinced, and filled with feelings of admiration, so much so that I was lost for words.

I explored the microfactory with great interest as I found every corner to be enlightening. Damien then pointed out a display.

"This shows even first-timers how to make cars, what each parts are for, and how to use the tools in the order that they would be used."

This was so much more than I had imagined.

Being "customer-oriented," "to be able to see things from the customers' perspective," is very important, but Local Motors had taken this to a new level. It was very impressive how well they understood their customers and willingly shared information and knowledge.

Every day, buyers will find a list of tasks they need to complete to build their car. Parts and processes are explained in straightforward, layman's terms. Videos are also provided for more complicated processes.

Every day, buyers will find a list of tasks they need to complete to build their car. Parts and processes are explained in straightforward, layman's terms. Videos are also provided for more complicated processes.

As I looked around the cozy factory, I saw the following words imprinted on the back of the car.

Made by you in America

These words seem to quietly encourage and cheer builders on. Not only do these words embody the value of the end product, but they also exemplify the treasured experiences - what the buyers learned while building the car, the passion that went into each turn of the spanner, the weekend they sacrificed, the joy they experienced as the car began to take shape, the relationships forged at the microfactory, and the ecstatic joy they felt when it was finally finished. (Although I hadn't built the car, I began to feel as though I had.)

The back end of the Rally Fighter.

The back end of the Rally Fighter.

"Made by you in America" imprinted on the back.

"Made by you in America" imprinted on the back.

目次へ移動 Platform for innovation - LM Labs

Microfactory's research lab, "LM Labs," is open from noon to 9:00pm on weekdays, and 10:00am to 4:00pm on Saturdays. At the "LM Labs," users and Local Motors' employees discuss and create prototypes as equals, as members of the community, as people who want to give shape to ideas. The lab is equipped with the space, machinery, tools, etc. necessary for trial and error.

Microfactory's research lab, "LM Labs," is open from noon to 9:00pm on weekdays, and 10:00am to 4:00pm on Saturdays. At the "LM Labs," users and Local Motors' employees discuss and create prototypes as equals, as members of the community, as people who want to give shape to ideas. The lab is equipped with the space, machinery, tools, etc. necessary for trial and error.

In addition to the Rally Fighter, I saw other cars, motorcycles, automobiles, and drones. Local Motors not only works on cars, but also has other on-going projects. I was already beyond impressed, when Damien added, "We create a platform for innovation. And we are involved in a wide-range of projects like the 'Rally Fighter in a Box,' 'Open Source Electric Skateboard,' and the '3D Printed Car Design Challenge.'"

"Things will become even more interesting when electric vehicles become more mainstream. With EVs, we will be able to control most of the drive system with software, even more so than with engine vehicles. And so software will become just as important as design. Cars nowadays deteriorate the more you drive it, but this won't necessarily be the case in the future. We will be able to continuously upgrade our cars by simply updating software. Software will bring out the true benefits of open source communities. And communities that can create software will become increasingly important. Since we create relationships based on trust and are accumulating know-how to manage such communities, we will have a strong competitive advantage in the years to come."

"Being able to design a car on the Internet, make it at a local factory, use state-of-the-art materials in the process, and to continue to improve its performance by upgrading software. This is the kind of business model we'll be looking at. What will be key is maintaining relationships with the clients, and to do so, we have to immerse ourselves in the community. To create something together, with our clients, we need frequent opportunities to touch base face-to-face, whether it be to improve design, assembly, or the production process. That is why we need a microfactory."

(Top left) Blue motorcycle "Racer." (Top right) White Racer. (Middle left) Electric or gas-powered, motorized bicycle, "Cruiser." (Middle right) Electric drift trike, "Verrado." (Bottom left) A model of the 3D printed car. (Bottom right) Two-seater "Open Tandem Project."

(Top left) Blue motorcycle "Racer." (Top right) White Racer. (Middle left) Electric or gas-powered, motorized bicycle, "Cruiser." (Middle right) Electric drift trike, "Verrado." (Bottom left) A model of the 3D printed car. (Bottom right) Two-seater "Open Tandem Project."

目次へ移動 Creating a community - Tapping into "Cognitive Surplus"

After exploring every inch of the microfactory, we had some time to sit down and exchange thoughts. At the end of our conversation, I asked Damien, "If we wanted to start something similar in Japan, what do you think we should do first?"

Damien answered without hesitation, "First, you need to create a community."

"To co-develop products with users and create new value like we do, in Japan, you first need to create a 'community,' a community of people with passion. There are a lot of people out there with 'Cognitive Surplus,' in other words people who have received excellent education and training, who are highly motivated, but are currently not using their skills to the fullest, who are more than happy to share their knowledge with the greater community. So creating a platform for tapping into 'Cognitive Surplus' is also important."

"At Local Motors, we provide an environment that allows anyone, who is part of the community, to actively share their ideas on design, technology, accessories, branding, etc. When you create a large community that enables clients and collaborators to help create new value, that community becomes part of the company, and a driving force for improving your competitive edge. Although it may be easy to mimic other companies' products and services, it's not so easy to try to create a community of people who are willing to act and contribute to the company."

"There are many Internet communities. But nothing beats real activism. It's important for people to come together, to spend time together in the same environment. Members of the community will help with product's last mile by building it themselves in the microfactory. Of course professionals will be there to provide assistance so that even first-timers will be able to build their cars. Getting together at the microfactory, sharing experiences in the same environment, is something an ordinary Internet company is unable to do."

"Members of the community not only help develop products, but they also become your clients. For example, with a car like the Rally Fighter, it would normally take a large company 2 years to design and 6 years to manufacture, but the Internet community helped complete the design in about 3 months, and we were able to manufacture the vehicles in 14 months. The Internet community helps speed up the design process, drive costs down, and also helps develop even better products. What's more, we've already done much of the market research along the way. And of course the community will naturally love the products because they helped create them."

"We hope that one day, there will be microfactories like ours in many areas that our community members live in, and that they can help create custom-order products with the help of local dealers. Members of the online community can work together with people across the world to create designs and assemble cars they helped developed in the local microfactory. And if it should ever break down, they can repair it themselves, and they can also return and recycle cars they no longer need. If there are people who need help building their cars, they can offer a hand. This will help inject energy into your community and help create fun, lasting relationships with members of the community."

Photo taken during a discussion with Damien. I was very impressed by his clear and convincing explanation about the company's vision.

Photo taken during a discussion with Damien. I was very impressed by his clear and convincing explanation about the company's vision.

目次へ移動

Conclusion - discover the joy, enlightenment, and playful spirit

Local Motors' innovative, thought-provoking initiatives may provide clues for bringing change to the society we currently live in - a mature society with a superabundance of things, where consumers are king, a society where, "as beneficiaries, we take what other people do for us for granted."

And above all, discovering the joy, the enlightenment, and the playful spirit of sharing ideas and creating new value, I believe, is paramount. In the future, this kind of spirit will be fundamental.

The microfactory is filled with such a magical feeling and a sense of belonging, once you step inside, you won't want to leave.

The microfactory is filled with such a magical feeling and a sense of belonging, once you step inside, you won't want to leave.

We should first start by taking action ourselves, by experiencing. Just jump in. Unleash the creativity within. And open up your heart and mind, and welcome new encounters. Perhaps this is the kind of attitude you need to create new communities and new teams.

By the time Damien waved me goodbye and I was leaving Arizona behind, I was sure. That this wasn't just a world of hobbies. The skepticism I had felt about "creating a car on the Internet" had completely dissipated.

Microfactory under the big blue sky.

Microfactory under the big blue sky.

Related Website:

Local Motors (http://localmotors.com)

Biography of Hidetoshi Fuchigami

Born 1975 in Hyogo prefecture. Graduated with a master's degree in Business Management from the University of Tsukuba. After working at the Nippon Telegraph and Telephone Corporation, he established a consulting/business development company, gaako Co., Ltd., in 2007. Fields he specializes in are strategic management, new business development, project management, contents business, and media-Internet convergence. He has worked as a member of the following committees: Ministry of Economy Trade and Industry's think tank for contents business formats, Ministry of Internal Affairs and Communications' National Institute of Information and Communications Technology, "ICT Venture Support Fund Advisory Committee.

Report, text, and photographs by: Hidetoshi Fuchigami

Translated by: Yuri Morikawa (oxygen inc.)